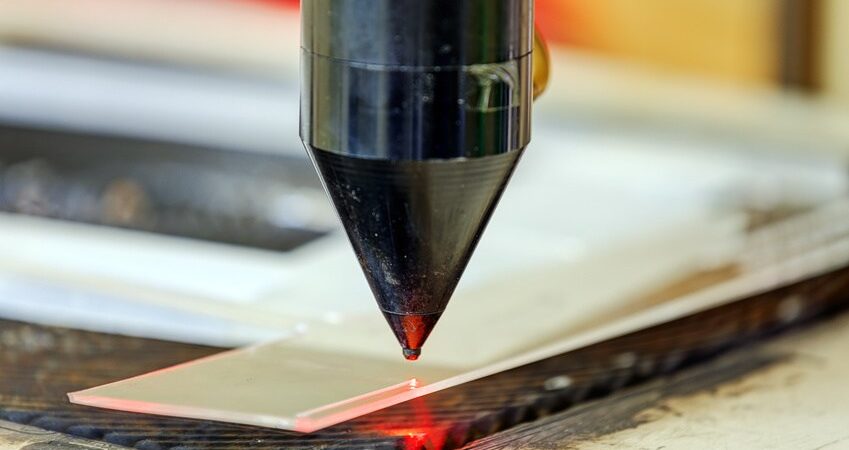

Laser cutting is an important aspect of metal fabrication. A laser cutter uses a high-powered laser beam to melt, burn, or vaporise material to create a high-quality finished edge surface. Many companies outsource from the best laser-cutting Perth companies for their advertising materials and signages.

This technology has plenty to offer in the benefits department, but just like laser etching aluminium and other manufacturing technology, it comes with a handful of disadvantages. Keep reading to learn more about laser cutting technology’s good and bad.

Advantages of Laser Cutting

High Precision

One of the most notable edges of laser cutting is its higher accuracy over similar thermal methods. With an accuracy of +/-0.1 mm, laser cutters can deliver high-precision results without needing an after-treatment. This type of technology makes perfect for projects with intricate and fine details, even on the most delicate and difficult materials.

High Speed

Laser cutting has a faster turnaround rate than traditional cutting methodssince it can quickly cut through any material up to a certain thickness. Laser cutting is ten times faster than bandsaws and almost one hundred times as fast as wire cutting.

Note that the speed at which a laser cutter cuts may depend on the power.

Material Compatibility

Contrary to popular belief, laser cutting is not exclusively performed on steel. You’d be surprised manufacturers also use laser cutting technology on non-metals like wood, paper, and with copper, and brass. Its high precision and versatility allow it to work perfectly well with various materials.

Disadvantages of Laser Cutting

Metal Thickness Limitations

While laser cutting uses a powerful machine to cut through metals, it may not be effective for thick plates. The average cut depth is 12 mm, which may take longer to finish.

Bigger and more powerful laser-cutting machines assisted by a specialist operator may be able to cut through practical limits. Still, other methods, such as waterjet and wire erosion cutting, can do the same much faster.

Dangerous Gases and Fumes

Laser cutting is compatible with a wide range of materials, but some of these materials can produce harmful gases when exposed to high, concentrated temperatures. For instance, fluoropolymers may produce phosgene gas, which is dangerous for humans to inhale. When processing certain materials, a controlled atmosphere is required.

Requires an Expert

It is not simple to operate a laser cutter. Misusing them may cause significant damage to the machine.

An expert is required to maximise a laser cutter’s features and to identify problems before they go out of hand quickly. Unfortunately, hiring a laser cutter specialist is expensive due to the limited available qualified professionals. Often, the solution is to outsource the operation instead.

Partnering with a Professional Company

Besides operating the machine, other risky disadvantages may give you problems during laser cutting. To avoid further issues like expensive upfront costs and energy consumption expenses, we recommend hiring services like Artcom Fabrication to provide you with high-quality laser cutting services.